Emissions Reporting

Operations at the Rookery South Energy Recovery Facility are tightly controlled by requirements set out in the plant’s Environmental Permit, which are regulated by the Environment Agency.

Rookery South provides monthly emissions reports for the public to view on this website. The regulatory authorities have approved this method of reporting as it is the simplest way to communicate this data to the public and other stakeholders. The same emissions data and reports are submitted to the Environment Agency for their independent assessment.

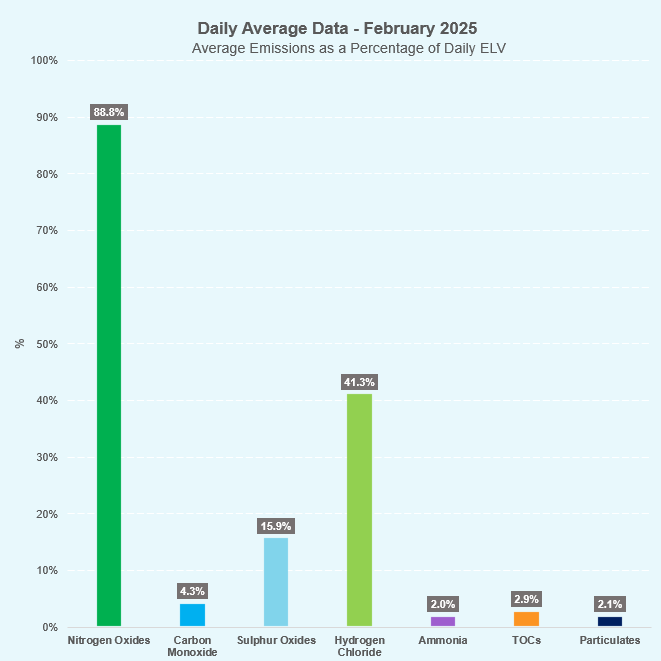

Monthly Emissions Summary - February 2025

We are committed to reducing emissions from our EfW facilities and to keeping these below the strict air emissions limits set by regulatory bodies. We employ sophisticated technologies to achieve superior environmental performance and minimise our impact.

State-of-the-art emissions control technologies

Boiler Design:

Our boilers are specifically designed to recover as much energy as possible out of the waste while minimising the formation of dioxins and ensuring complete combustion, including that of volatile organic compounds (VOCs) and other organic compounds.

Nitrogen Oxides (NOx) Control:

Our facilities are equipped with a selective non-catalytic NOx reduction (SNCR) system, which injects ammonia into the furnace to chemically convert NOx into nitrogen, an inert gas, and water.

Carbon Injection:

Activated carbon is added to the flue gas stream as it exits the boiler. Contaminants such as mercury and dioxins adsorb to the surface of the carbon so they can be removed downstream in the baghouse filter.

Scrubber:

A scrubber neutralises over 95% of acid gases, including sulphur dioxide and hydrochloric acid, by spraying a lime slurry into the exhaust stream.

Baghouse:

Operating like a very efficient vacuum cleaner, the baghouse filter removes 99.5% of the particulate matter from the combustion gases. As air is drawn through the baghouse, particulate matter is caught on the surfaces of the bags. Periodically, the bags are cleaned by pulsing the bags with a strong jet of air. The particulates are transferred to silos.

Emission Monitoring:

Rookery South ERF operates under strict air emissions control limits. We use a combination of continuous emission monitoring systems that monitor emissions 24 hours a day, seven days a week.